ALD® System

Working Principle

The Equipment

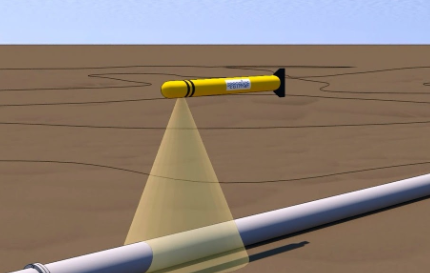

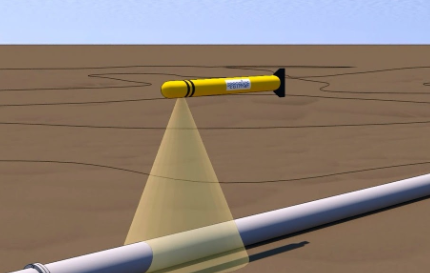

The system is mainly composed by an underwater acoustic sensor, a POD (underwater electronic unit), a transmission line, a receiving unit and a PC based processing and display software. The sensor and the transmission line are different depending on the inspection techniques while the other components are common to all applications: while the sensor is driven along the pipeline or positioned close to a flange or connection, the receiver puts the operator in condition of identifying an eventual leak signal.

On the base of the mean used for driving the sensor, different inspection techniques and relative equipment are available: Towed fish, Diver handled, Vertical deployment, and ROV Installed

A proprietary software allows to evaluate in real time the signal acquired and its evolution along the track. This software performs analysis of the acquired data from statistic, energetic and a spectral point of view. This is one of the key points of the whole system, and of the relative international patent.

The leak signal generated by a leak is mainly composed by ultrasound, the ALD receiver shifts this signal to audible lower frequency generating a “virtual audio”.

ALD® has the following advantages

- Not Affected By Current, Turbidity, Visibility, Ambient Noise

- No Need to Stop Production

- High Sensitivity for Small Leak Detection

- 100% Reliability: Never Left Behind A Leaking Pipeline

- Rapidity

- Works on Buried Pipelines